Latest news

Trail Angels on Cinderella

Last weekend, an energetic and skilled crew of BTCEB trail angels, led by Director Tom Gandesbery, was at Joaquin Miller Park working on the Cinderella Trail. Cinderella, or Cindy to her friends, is one of the funnest and most challenging narrow trails in the whole Bay Area. Cindy is…

Spread Positivity on the Trails

IMBA Ride Vibes are an educational, pro-bike advocacy tool to promote respect, inclusivity, safety and enjoyment on the trails. Ride Vibes can cultivate a positive community for all people and all levels of experience within mountain biking, and across trail user groups. Here’s to good trail vibes for all.

Marinduro 2024: Crazy Muddy Fun!

Marinduro 2024 was EPIC and we’re keeping the party going! The A4Bikes Crew reports that on Saturday, March 30th, after days of rain over the Marin Coastal Range, 324 shredders came out to play on their beloved home trails at Camp Tamarancho. With a *new* Stage 6, over 80 volunteers, rowdy trails,…

Park Sponsored Trail Work at Tilden!

On Wednesday on March 27th, 2024 an eager group of trail enthusiasts gathered in Tilden Park to improve a section of trail under the direction and leadership of the East Bay Regional Parks District. This work session brought together high school mountain bike coaches from the El Cerrito,…

BTCEB Increases Support for Youth MTB Teams

BTCEB has expanded our support of East Bay middle and high school mountain bike teams in an effort to get more kids on bikes, promote trail stewardship and advocacy, and build a stronger trail community. Photo courtesy Oakland Composite Instagram This cycle BTCEB donated $13,000 total to 13 teams…

Canyon Loop Trail Reroute at Fernandez Ranch Work Day

V-O-Cal will be leading a re-route of the Canyon Loop Trail at Fernandez Ranch to bypass an old ranch road that becomes impassably muddy after rain. The redesigned trail will meander through forests, across grasslands and into a quaint buckeye grove and features a 5% decrease in elevation and several…

Trail One Components Continues BTCEB Support

Trail One found Brian Kennedy presents BTCEB Advocacy Director Scott Bartlebaugh $4,000 donation from the proceeds of the Crockett Handlebars. Trail One Components has made a second and even more generous donation of $4000 from their Trail Treasury to the Bicycle Trails Council of the East Bay. The…

How to Donate to BTCEB

Looking for a way to increase your support of BTCEB’s mission to free the singletrack? In addition to your paid membership, we’d really appreciate your donations. Use this Paypal link or the donate button bellow to donate directly to BTCEB. You can make one-time or recurring contributions to BTCEB….

2023 Advocacy Wrap Up – Whew!

2023 was another busy year for advocacy. As typical it’s a number of small steps moving at a glacial pace, but 2023 included very encouraging steps with progress on the Briones Pilot program, Wildcat Flow Trail Project, and Lime Ridge Flow Trail Project among others. In some cases…

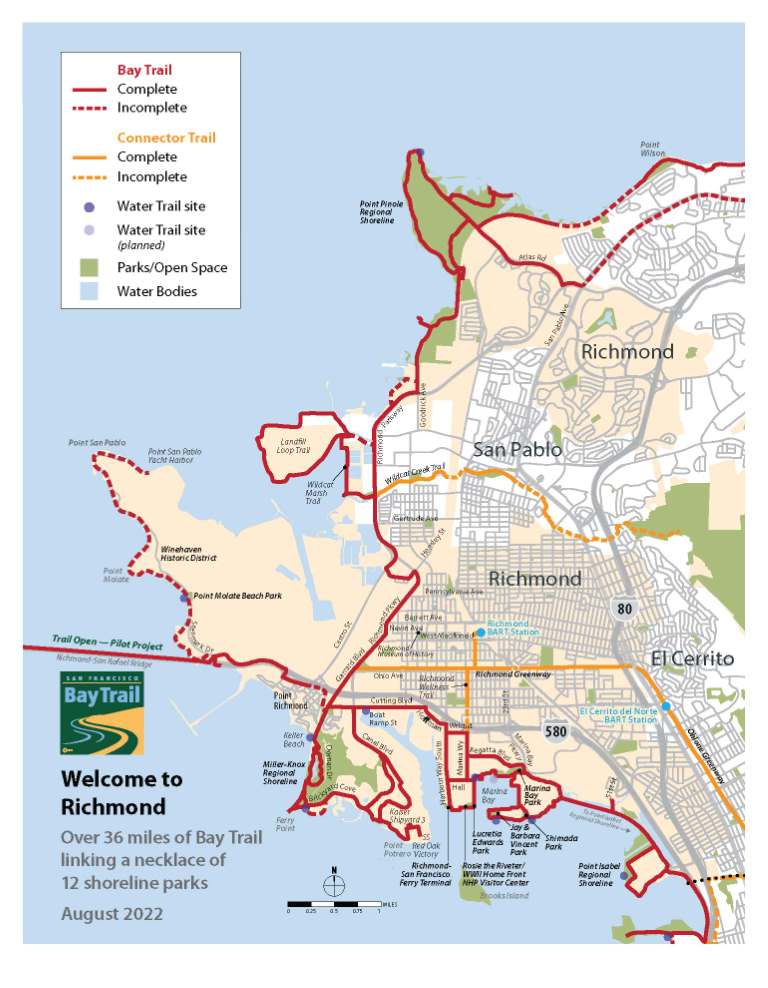

Bay Trail Richmond 2024 Report

TRAC, the Trails for Richmond Action Committee has released their 25th annual Bay Trail Richmond New Year Report. This colorful report summarizes progress toward completing and improving the Bay Trail in Richmond during 2023. Highlights include: – Point Molate Bay Trail – Richmond San Rafael Bridge Trail – Extending the trail from…

BTCEB Club Elections Upcoming

You may have seen our pleas the last few months but we are STILL looking for passionate individuals interested in mountain biking that want to give back to the sport, community, and lands that that we all love. Does that sound like you? Would you like to be part…

Mount Diablo Trails Alliance

Mark Moskowitz and Eric Johnston have formed Mount Diablo Trails Alliance and have set in motion some terrific trail stewardship and advocacy efforts at Mount Diablo State Park. They have been performing trail maintenance on MDSP trails for several years and have built a constructive relationship with the park…

Or join the group on FaceBook

Our FaceBook group has great discussion from riders all over the East Bay. Learn about trail conditions and upcoming rides.